Potassium Monopersulfate Compound is gaining traction in various industries, especially in water treatment and sanitation. According to a report by the World Health Organization, effective sanitation can significantly reduce waterborne diseases. The compound acts as an oxidizing agent, making it valuable in disinfection processes.

In addition, the use of Potassium Monopersulfate Compound in swimming pools has increased, with a 20% rise noted in recent years. Many pool owners prefer it due to its effectiveness against bacteria and algae without the harsh smell of chlorine. However, improper usage can lead to inadequate disinfection. Thorough understanding is essential.

However, there are concerns about its handling. The compound can be irritating to the skin and eyes. Users must ensure proper safety protocols are in place. Industry data shows that while effective, misuse occurs in 15% of cases. This raises the need for comprehensive guidelines on its effective application. Insights into these parameters can transform how we utilize Potassium Monopersulfate Compound.

Potassium monopersulfate (PMPS) is a powerful oxidizing agent. Its unique composition makes it ideal for various applications. This compound typically includes potassium sulfate and other sulfates. PMPS is known for its stability and effectiveness in different pH levels, making it versatile.

One of the key properties of PMPS is its ability to release active oxygen. The decomposition of PMPS leads to the formation of reactive species. This is particularly valuable in water treatment. According to industry reports, PMPS can reduce pathogen levels significantly. Studies show a reduction of up to 99% in some bacteria. However, the efficiency can vary depending on the environmental conditions.

Despite its advantages, there are some considerations. PMPS can be less effective in highly contaminated waters. It requires proper dosage to achieve the desired results. Over-application can lead to unwanted side effects. Adjusting the concentration based on specific needs is crucial. Experimentation may be necessary to find the right balance.

Potassium monopersulfate is a powerful oxidizing agent. Its effectiveness in water treatment has gained attention in recent years. In fact, industry reports indicate a growing trend in its use for disinfection and oxidation. This compound effectively reduces pathogens and organic contaminants in water.

One major application is in pool sanitation. Many facilities utilize potassium monopersulfate for its rapid acting properties. Research shows that it can reduce chlorine demand by up to 50%. This means users can maintain cleaner water with less chemical input. Moreover, its low environmental impact makes it an attractive choice for operators.

However, the application of potassium monopersulfate isn't without challenges. Dosage control is critical. Too much can lead to unwanted reactions, while too little may not achieve desired results. Facilities must constantly monitor water quality, ensuring that the chemical reduces contaminants effectively. Inconsistent application can reflect poorly on treatment efficacy and public perception.

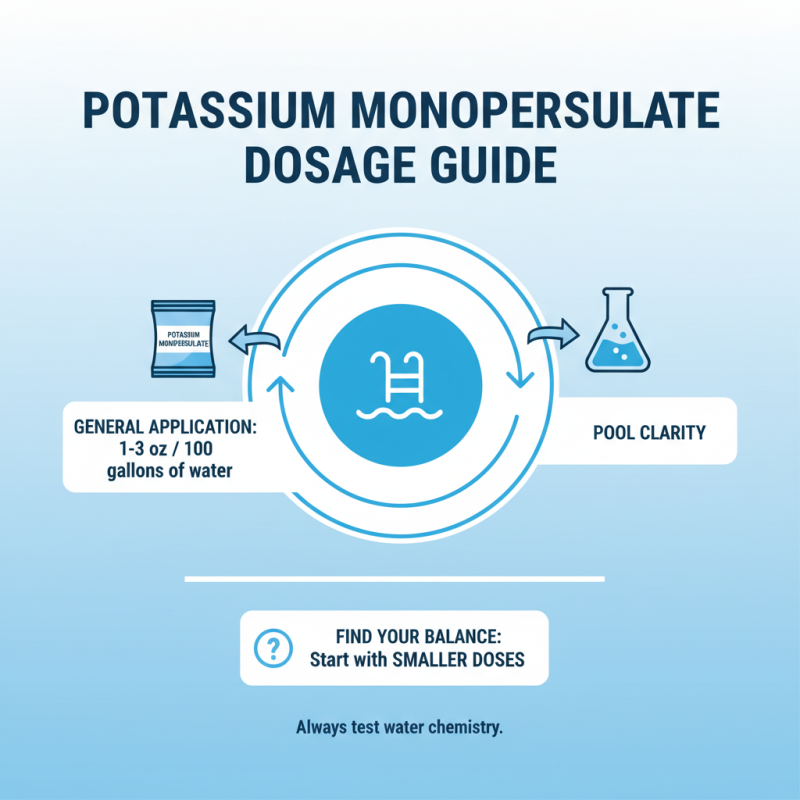

When using potassium monopersulfate, understanding dosage is critical. For general applications, a typical range is 1 to 3 ounces per 100 gallons of water. This is effective for maintaining water clarity in pools. However, some may find this amount too strong. Testing with smaller doses can help find the right balance.

Application techniques also matter. Dissolve the compound in a separate container first. This prevents clumping and ensures even distribution. Pour it around the pool perimeter, rather than directly in the center. This method promotes better mixing. Some users report streaks and uneven results when added improperly.

Keep an eye on your water chemistry after application. Adjustments may be necessary depending on the initial water quality. Sometimes, the desired clarity is not immediate. Patience is key. Adjusting the dosage based on feedback can lead to improvements. Reflecting on past experiences can guide future use.

When handling potassium monopersulfate, safety is paramount. This compound can be reactive, so precautions are essential. Always wear proper personal protective equipment, including gloves, goggles, and masks. These items protect your skin, eyes, and respiratory system from potential irritation. Even small spills can lead to significant hazards.

Store the compound in a cool, dry place, away from direct sunlight. It’s best to keep it in a tightly sealed container. Be cautious when measuring. The slightest error could lead to dangerous reactions. If inhaled, it can cause respiratory issues. Have a first aid kit nearby just in case.

Education is key. Familiarize yourself with emergency procedures before using the compound. It’s easy to overlook details when you're rushed. Make sure all users are trained. Misunderstandings can lead to accidents. Always read labels and safety data sheets. Recognizing risks before they become issues is crucial to safe usage.

This chart illustrates the effectiveness and safety ratings of potassium monopersulfate in various applications and its handling precautions. As shown, it is highly effective in pool maintenance and cleaning but requires careful handling to ensure safety and minimize environmental impact.

When using potassium monopersulfate, environmental considerations are vital. This compound is often chosen for its effectiveness in water treatment and sanitation. However, its application must be approached carefully. Potential impacts on water systems can occur if not managed properly.

One concern involves its reactivity. While it's an excellent oxidizing agent, it can form by-products harmful to aquatic life. Regular testing of water parameters is essential. Misjudging dosage can lead to chemical imbalances. Always consider local ecosystems when applying this compound. Each region may respond differently.

Furthermore, consider the packaging and disposal of potassium monopersulfate. Improper disposal could result in leaching into soil and groundwater. It is crucial to follow safety guidelines. Sustainable practices should be a priority. Reflect on the long-term effects of chemical use on the environment and the need for alternative methods. Mindfulness in application can create a balance between effectiveness and environmental health.

| Aspect | Consideration | Effective Usage | Environmental Impact |

|---|---|---|---|

| Concentration | Optimal range is 2-5%. | Dilute according to manufacturer's recommendations. | Reduces risk of excess chemical discharge. |

| Temperature | Best efficacy at 20-30°C. | Ensure proper temperature before application. | Minimizes uncontrolled reactions. |

| pH Level | Ideal pH is between 6-8. | Adjust acidity or alkalinity as needed. | Limits potential environmental disruptions. |

| Application Method | Common methods include shock dosing and continuous feed. | Choose method based on water quality and usage site. | Optimizes chemical use, reducing waste. |

| Monitoring | Regular monitoring of system health is necessary. | Use control systems to adjust dosing automatically. | Enhances safety and reduces chemical footprint. |